Tower Ceramic Structured Packing

High-Performance Tower Ceramic Structured Packing for Efficient Mass Transfer

Superior Quality Tower Ceramic Structured Packing for Various Industrial Applications

Tower Ceramic Structured Packing

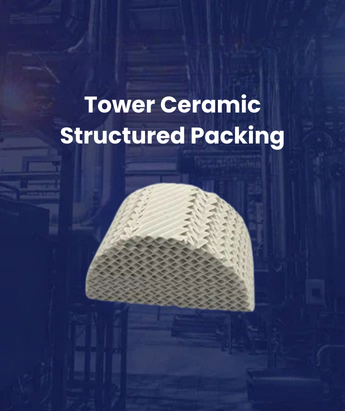

Tower Ceramic Structured Packing is a highly efficient solution designed for modern separation processes. Made from ceramic corrugated sheets arranged in parallel to form cylindrical units, this packing offers exceptional separating efficiency compared to traditional loose packing. Its unique structure ensures a low-pressure drop, increased operating flexibility, and optimized liquid distribution, making it ideal for applications requiring superior performance and reliable results.

As a trusted Tower Ceramic Structured Packing manufacturer, we provide units that combine durability with high efficiency. Each packing element is engineered to maximize liquid treatment while minimizing energy losses. Whether for industrial towers or complex chemical processes, Tower Ceramic Structured Packing delivers consistent performance, reduced amplifying effects, and enhanced operational stability, making it the preferred choice for engineers and plant operators worldwide.

Applications of Tower Ceramic Structured Packing

Tower Ceramic Structured Packing finds extensive use across multiple industries due to its durability and high efficiency. It is widely employed in chemical processing, petrochemical plants, and other industrial separation systems. The packing provides excellent support for liquids and gases, making it a reliable choice for processes that require precise mass transfer and optimal performance in demanding conditions.

Primary applications include:

- Enhancing separation efficiency in distillation and absorption towers.

- Supporting chemical reactions by improving contact between phases.

- Serving as structural elements in industrial towers to maintain consistent flow and distribution.

- Reducing pressure drop while optimizing liquid handling and treatment.

Advantages of Tower Ceramic Structured Packing

Tower Ceramic Structured Packing offers numerous benefits that make it an ideal choice for industrial applications. Its long service life is ensured by high-quality ceramic materials and precise manufacturing, allowing for consistent performance over extended periods. The robust design enhances safety by reducing the risk of breakage or operational failure during critical processes.

Additional advantages include:

- Cost-Effective: Reliable performance lowers maintenance needs and minimizes downtime.

- Eco-Friendly: Manufactured from sustainable materials, reducing environmental impact.

- Operational Efficiency: Optimized structure ensures better liquid distribution, low-pressure drop, and maximum separation efficiency, making it a preferred solution for engineers and plant operators worldwide.

Features of Tower Ceramic Structured Packing

Tower Ceramic Structured Packing is designed to deliver superior performance in industrial separation processes. Its corrugated ceramic sheets are arranged in a structured pattern, ensuring uniform liquid distribution and maximizing contact between gas and liquid phases. This innovative design improves separation efficiency while maintaining low-pressure drop and high operational stability.

Key features include:

- High Efficiency: Structured design significantly enhances mass transfer compared to random packing.

- Durable Construction: Made from premium ceramic materials for long-lasting performance.

- Versatile Application: Suitable for chemical, petrochemical, and other industrial towers.

- Low Maintenance: Optimized structure reduces fouling and downtime, improving overall cost-effectiveness.

We, the SKJ Group, founded in 2019, are one of the leading manufacturers of high-tech ceramic materials and tower packings.

Tower Ceramic Structured Packing stands out as a reliable and efficient solution for modern separation processes. Its structured ceramic design ensures optimal contact between liquid and gas phases, delivering higher separation efficiency and consistent performance. The packing reduces pressure drop, improves liquid distribution, and supports long-term operational stability, making it ideal for demanding industrial applications.

Choosing Tower Ceramic Structured Packing from a trusted distributor, guarantees durable, high-quality materials, cost-effective performance, and eco-friendly design. Whether for chemical, petrochemical, or other industrial towers, this packing provides superior reliability and operational flexibility that engineers and plant operators can depend on.

Specifications of Tower Ceramic Structured Packing

Tower Ceramic Structured Packing is crafted from high-quality ceramic materials to ensure durability and long-lasting performance in industrial applications. Its corrugated and structured design is available in various shapes and sizes, tailored to meet the needs of different tower configurations.

- Material: Premium ceramic for strength and efficiency

- Shape: Corrugated and structured for optimal liquid-gas contact

- Sizes: Available in multiple dimensions to suit industrial towers

- Color Options: Neutral or customized colors to align with specific setups

- Compliance: Manufactured to meet international quality and safety standards

FAQ's About Tower Ceramic Structured Packing

What is Tower Ceramic Structured Packing?

Tower Ceramic Structured Packing consists of corrugated ceramic sheets arranged in a structured pattern to form cylindrical units, providing high separation efficiency, low-pressure drop, and reliable performance in industrial towers.

What are the advantages of using Tower Ceramic Structured Packing?

It offers long service life, low maintenance, improved separation efficiency, optimized liquid distribution, and eco-friendly design, making it a cost-effective and reliable solution for various chemical and industrial tower processes.

What industries can benefit from Tower Ceramic Structured Packing?

It is widely used in chemical processing, petrochemical, pharmaceutical, and other industrial towers where efficient gas-liquid separation, high performance, and operational stability are critical.

Can Tower Ceramic Structured Packing be customized to meet specific requirements?

Yes, the packing can be tailored in size, shape, and color to suit specific tower dimensions, process requirements, and industrial setups for optimal performance and compatibility.

How should Tower Ceramic Structured Packing be installed and maintained?

Installation requires careful placement in the tower to maintain uniform flow, while maintenance is minimal due to durable ceramic construction, ensuring long-term efficiency with periodic inspections for optimal performance.

Is Tower Ceramic Structured Packing environmentally friendly?

Yes, it is made from sustainable ceramic materials, reduces energy consumption due to low-pressure drop, and supports eco-friendly industrial operations without compromising performance or durability.

What quality certifications does SKJ Overseas hold for Tower Ceramic Structured Packing?

SKJ Overseas ensures all Tower Ceramic Structured Packing products meet international quality and safety standards, providing certified, high-performance packing for reliable industrial applications worldwide.